- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

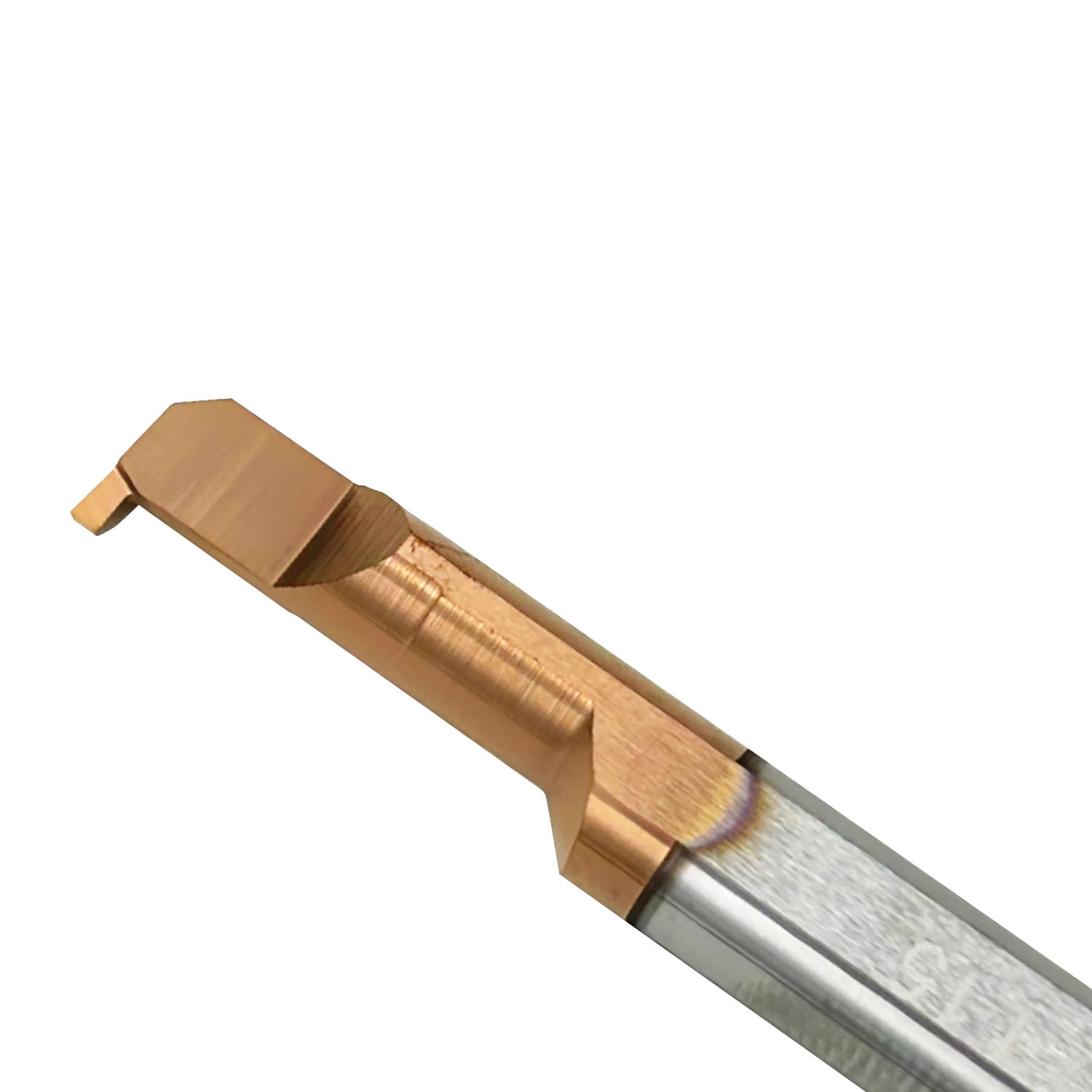

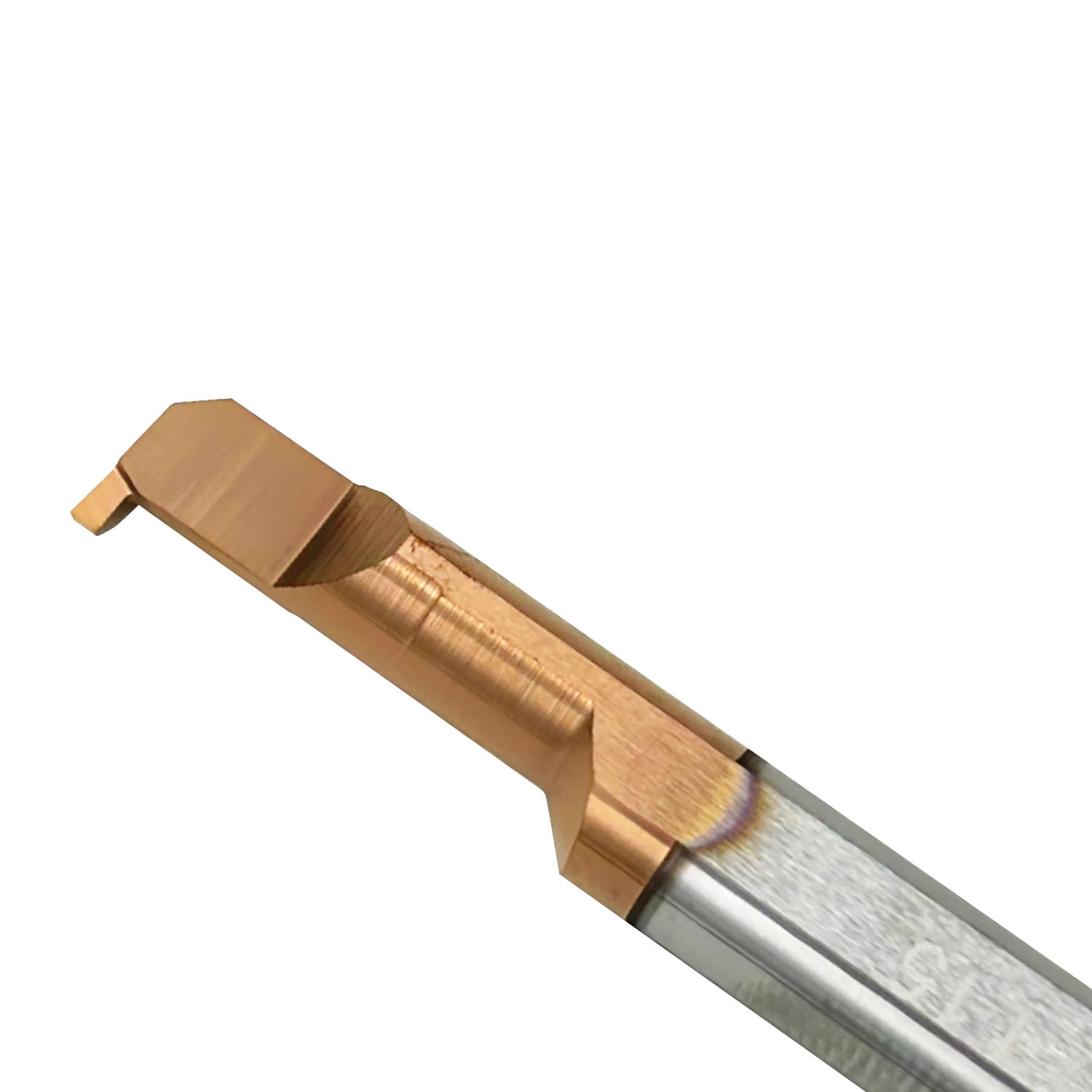

MNR 1R0.05 L3

ZIFAN

Introduction to Small-Angle Drill Bits

1. Definition

A small-diameter boring tool, as the name suggests, is a boring tool specifically designed for machining small-diameter internal holes. Generally, we classify boring tools with diameters below Φ20mm, especially those within the range of Φ3mm to Φ12mm, as small-diameter boring tools. Due to the extremely limited processing space, extremely high requirements are imposed on the structure, rigidity, accuracy and material of the tool.

2. Main Applications

Small-diameter boring tools are mainly used to drill high-precision holes in solid materials or to perform fine processing on existing small holes. Common application fields include:

· Precision mechanical manufacturing: such as processing small holes in precision spindles, hydraulic valve blocks, nozzles, etc.

· Mold industry: processing pin holes and cooling water holes in molds.

· Aerospace: critical components such as engine blade cooling holes, fuel nozzles, etc.

· Automotive industry: engine fuel systems (such as fuel injectors), transmission valve bodies, etc.

· Medical devices: surgical instruments, implants, etc., which require extremely high cleanliness and precision.

3. Key Features and Technical Requirements

Compared with conventional boring tools, the small-diameter boring tool has the following notable features:

· High precision: Capable of consistently achieving IT7-IT8 level or even higher hole diameter tolerances, as well as excellent surface finish.

· High rigidity: The tool holder is slender, and to avoid vibration and tool breakage during processing, high-rigidity materials (such as hard alloy/tungsten steel) must be used for manufacturing.

· Small size: The overall structure is very compact, and the tool head is extremely small to fit into narrow processing spaces.

· Difficult chip removal: The space inside the hole is small, making it difficult for chips to be discharged. This can cause surface scratches or damage to the tool. Therefore, excellent groove design and chip-breaking capabilities are crucial.

· Fine adjustment capability: To achieve micrometer-level hole diameter adjustments, small-diameter boring tools usually come with precise fine adjustment mechanisms.

4. Common Types

According to the structure and adjustment method, small-diameter boring tools can be mainly classified into the following categories:

a. Integral hard alloy boring cutter

· Description: The handle and the head of the tool are made of a single piece of hard alloy.

· Advantages: Excellent rigidity, strong shock resistance, and the highest precision.

· Disadvantages: The diameter is fixed and cannot be adjusted. Usually, a complete set of tools with different diameters needs to be equipped, which results in higher costs.

· Applications: Large-scale, fixed-diameter, high-precision hole processing.

b. Adjustable small boring tool

· Description: This is the most common and flexible type. It adopts a modular design and typically includes:

· Hard alloy shank: Provides the rigidity of the main body.

· Replaceable precision boring head/holder: Installed at the front end of the shank, with a fine-tuning screw on it.

· Advantages:

· Diameter adjustable: Through the fine-tuning screw, the hole diameter can be precisely adjusted within a certain range (e.g., ±0.15mm).

· Cost-effective: By simply replacing different-sized boring heads, a range of diameters can be covered, without the need to purchase a large number of complete shanks.

· High flexibility: The same shank can be paired with different lengths of boring heads to adapt to holes with different depth-to-diameter ratios.

· Fine-tuning method: Usually, it is fine-tuned using a scale dial or a differential screw, with an adjustment accuracy of up to 1-2μm.

c. Modular boring tool system (for small holes)

· Description: Composed of the handle, extension rod, reducing sleeve and precision boring head modules.

· Advantages: The combination is extremely flexible, enabling the construction of a very long boring tool that maintains good rigidity and can be used for processing deep holes.

· Applications: Suitable for processing small deep holes with a depth-to-diameter ratio greater than 5 times the diameter.

5. Key Selection Points

When choosing and using small-diameter boring tools, the following points should be given special consideration:

1. Processing hole diameter and range: Clearly define the minimum and maximum hole diameters that need to be processed, as well as the adjustment range.

2. Processing depth/diameter ratio: Select a sufficiently rigid and as short as possible tool holder based on the depth of the hole. The larger the depth-to-diameter ratio, the higher the requirement for the rigidity of the cutting tool.

3. Machine tool performance: Small hole boring requires high radial runout and overall stability of the spindle. Ensure the machine tool has the corresponding accuracy.

4. Blade material and groove type: Choose a hard alloy material suitable for the processed material (such as steel, stainless steel, aluminum alloy, etc.) and a sharp groove type to reduce cutting force and improve chip removal.

5. Cooling method: It is strongly recommended to use internal cooling tools. High-pressure internal cooling fluid can effectively cool the tool tip and help push the chips out of the hole, which is the key to ensuring the success of small hole boring.

6. Cutting parameters: Adopt a strategy of high rotational speed, small cutting depth, and medium feed rate to control cutting force and cutting heat.

Introduction to Small-Angle Drill Bits

1. Definition

A small-diameter boring tool, as the name suggests, is a boring tool specifically designed for machining small-diameter internal holes. Generally, we classify boring tools with diameters below Φ20mm, especially those within the range of Φ3mm to Φ12mm, as small-diameter boring tools. Due to the extremely limited processing space, extremely high requirements are imposed on the structure, rigidity, accuracy and material of the tool.

2. Main Applications

Small-diameter boring tools are mainly used to drill high-precision holes in solid materials or to perform fine processing on existing small holes. Common application fields include:

· Precision mechanical manufacturing: such as processing small holes in precision spindles, hydraulic valve blocks, nozzles, etc.

· Mold industry: processing pin holes and cooling water holes in molds.

· Aerospace: critical components such as engine blade cooling holes, fuel nozzles, etc.

· Automotive industry: engine fuel systems (such as fuel injectors), transmission valve bodies, etc.

· Medical devices: surgical instruments, implants, etc., which require extremely high cleanliness and precision.

3. Key Features and Technical Requirements

Compared with conventional boring tools, the small-diameter boring tool has the following notable features:

· High precision: Capable of consistently achieving IT7-IT8 level or even higher hole diameter tolerances, as well as excellent surface finish.

· High rigidity: The tool holder is slender, and to avoid vibration and tool breakage during processing, high-rigidity materials (such as hard alloy/tungsten steel) must be used for manufacturing.

· Small size: The overall structure is very compact, and the tool head is extremely small to fit into narrow processing spaces.

· Difficult chip removal: The space inside the hole is small, making it difficult for chips to be discharged. This can cause surface scratches or damage to the tool. Therefore, excellent groove design and chip-breaking capabilities are crucial.

· Fine adjustment capability: To achieve micrometer-level hole diameter adjustments, small-diameter boring tools usually come with precise fine adjustment mechanisms.

4. Common Types

According to the structure and adjustment method, small-diameter boring tools can be mainly classified into the following categories:

a. Integral hard alloy boring cutter

· Description: The handle and the head of the tool are made of a single piece of hard alloy.

· Advantages: Excellent rigidity, strong shock resistance, and the highest precision.

· Disadvantages: The diameter is fixed and cannot be adjusted. Usually, a complete set of tools with different diameters needs to be equipped, which results in higher costs.

· Applications: Large-scale, fixed-diameter, high-precision hole processing.

b. Adjustable small boring tool

· Description: This is the most common and flexible type. It adopts a modular design and typically includes:

· Hard alloy shank: Provides the rigidity of the main body.

· Replaceable precision boring head/holder: Installed at the front end of the shank, with a fine-tuning screw on it.

· Advantages:

· Diameter adjustable: Through the fine-tuning screw, the hole diameter can be precisely adjusted within a certain range (e.g., ±0.15mm).

· Cost-effective: By simply replacing different-sized boring heads, a range of diameters can be covered, without the need to purchase a large number of complete shanks.

· High flexibility: The same shank can be paired with different lengths of boring heads to adapt to holes with different depth-to-diameter ratios.

· Fine-tuning method: Usually, it is fine-tuned using a scale dial or a differential screw, with an adjustment accuracy of up to 1-2μm.

c. Modular boring tool system (for small holes)

· Description: Composed of the handle, extension rod, reducing sleeve and precision boring head modules.

· Advantages: The combination is extremely flexible, enabling the construction of a very long boring tool that maintains good rigidity and can be used for processing deep holes.

· Applications: Suitable for processing small deep holes with a depth-to-diameter ratio greater than 5 times the diameter.

5. Key Selection Points

When choosing and using small-diameter boring tools, the following points should be given special consideration:

1. Processing hole diameter and range: Clearly define the minimum and maximum hole diameters that need to be processed, as well as the adjustment range.

2. Processing depth/diameter ratio: Select a sufficiently rigid and as short as possible tool holder based on the depth of the hole. The larger the depth-to-diameter ratio, the higher the requirement for the rigidity of the cutting tool.

3. Machine tool performance: Small hole boring requires high radial runout and overall stability of the spindle. Ensure the machine tool has the corresponding accuracy.

4. Blade material and groove type: Choose a hard alloy material suitable for the processed material (such as steel, stainless steel, aluminum alloy, etc.) and a sharp groove type to reduce cutting force and improve chip removal.

5. Cooling method: It is strongly recommended to use internal cooling tools. High-pressure internal cooling fluid can effectively cool the tool tip and help push the chips out of the hole, which is the key to ensuring the success of small hole boring.

6. Cutting parameters: Adopt a strategy of high rotational speed, small cutting depth, and medium feed rate to control cutting force and cutting heat.